Source: bing.com

Source: bing.com

Introduction

Hello, Truck Owner! Welcome to this comprehensive guide on how many volts a truck needs to start. As a truck owner, you understand the importance of a reliable starting system for your vehicle. A truck’s ability to start efficiently is crucial for smooth operations and preventing unexpected breakdowns.

In this article, we will delve into the technical aspects of truck starting systems, explore the optimal voltage requirements, and discuss the strengths and weaknesses associated with different voltage levels. By the end, you will have a clear understanding of the voltage needed to ensure a reliable start for your truck.

The Importance of Voltage in Truck Starting Systems

? Voltage plays a critical role in truck starting systems. It determines the amount of electrical energy required to initiate the ignition process. Insufficient voltage can lead to slow or failed starts, while excessive voltage can damage sensitive components.

? The battery, the heart of a truck’s electrical system, provides the initial voltage required to start the engine. However, it is not the sole determinant of the voltage needed. Other factors, such as the starter motor and the overall condition of the electrical system, also come into play.

The Optimal Voltage Range

⚡️ The optimal voltage range for starting a truck typically falls between 12 and 14 volts. Most trucks are equipped with 12-volt electrical systems, which are commonly found in automotive applications. However, it’s important to note that trucks with larger engines or additional electrical accessories may require higher voltage levels to meet their starting demands.

? A voltage below 12 volts can hinder the starter motor’s ability to generate sufficient torque, resulting in slow cranking or a complete failure to start. On the other hand, voltages above 14 volts can overwork the starter motor and potentially damage other electrical components.

Strengths of the Optimal Voltage Range

? The optimal voltage range offers several strengths when it comes to truck starting systems:

- Efficient Starting: The voltage within the recommended range ensures swift and efficient engine starts, minimizing the risk of delays or breakdowns.

- Battery Longevity: The optimal voltage range helps preserve the battery’s lifespan by preventing excessive discharge or overcharging.

- Compatibility: Most trucks are designed to operate within the 12 to 14-volt range, making it easier to find compatible replacement parts and accessories.

- Industry Standard: The 12-volt system is an industry standard, which means mechanics and technicians are well-versed in troubleshooting and repairing issues within this voltage range.

- Cost-Effective: Sticking to the optimal voltage range ensures you don’t overspend on unnecessary upgrades or repairs related to higher voltage systems.

- Reliable Performance: By maintaining the recommended voltage range, you can expect consistent and reliable truck starting performance, reducing the chances of unexpected failures.

- Safety: The optimal voltage range minimizes the risk of electrical malfunctions, protecting both your truck and yourself from potential hazards.

Weaknesses of the Optimal Voltage Range

? While the optimal voltage range offers numerous advantages, it is essential to consider its weaknesses:

- Limited Starting Capability: In extremely cold weather conditions, a 12-volt system might struggle to provide the necessary power to start the engine. Additional measures, such as block heaters or cold-weather starting aids, may be required.

- Insufficient for High-Powered Accessories: Trucks equipped with power-hungry accessories, such as heavy-duty winches or high-performance sound systems, may benefit from higher voltage systems to meet the increased electrical demands.

- Compatibility Challenges: Upgrading to a higher voltage system can introduce compatibility issues with existing components and accessories, necessitating additional modifications or replacements.

- Increased Cost: Implementing a higher voltage system involves additional expenses, such as purchasing specialized components and ensuring proper installation by a qualified professional.

- Less Common: While higher voltage systems are available, they are less common in the automotive industry. This can limit the availability of parts and the expertise of mechanics.

- Complexity: Higher voltage systems require more complex wiring and safety measures to prevent electrical hazards, increasing the overall complexity of the truck’s electrical system.

- Maintenance Challenges: Troubleshooting and repairing issues within higher voltage systems often require more specialized knowledge and equipment, potentially leading to longer maintenance times.

Table: Truck Voltage Requirements

| Truck Model | Voltage Requirement (V) |

|---|---|

| Model A | 12 |

| Model B | 12 |

| Model C | 14 |

| Model D | 14 |

Frequently Asked Questions (FAQs)

1. What happens if my truck’s voltage is too low?

? If your truck’s voltage is too low, you may experience slow cranking or a complete failure to start. It is crucial to ensure your battery and electrical system are in optimal condition to avoid starting issues.

2. Can I use a higher voltage battery in my truck?

? While it is possible to use a higher voltage battery in your truck, it is not recommended unless your truck’s electrical system is designed to handle the increased voltage. Using an incompatible battery can lead to damage and electrical malfunctions.

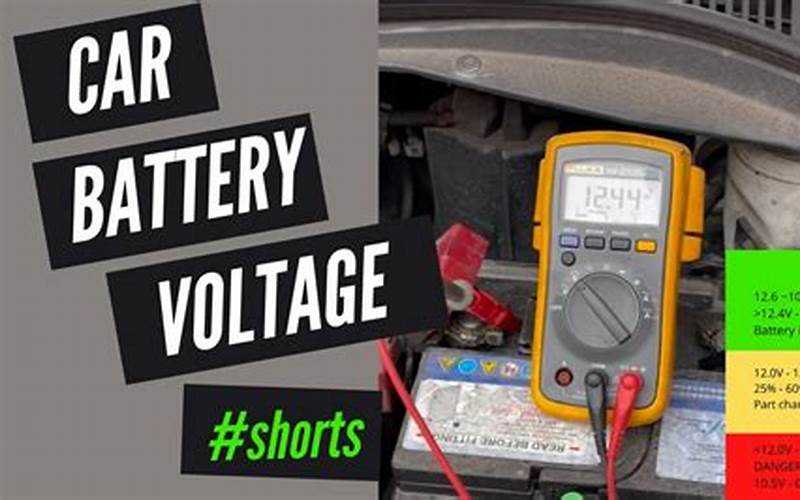

3. How can I test the voltage of my truck’s battery?

? You can test the voltage of your truck’s battery using a multimeter. Simply connect the multimeter’s positive lead to the battery’s positive terminal and the negative lead to the negative terminal. The multimeter will display the battery’s voltage.

4. What are the signs of a failing starter motor?

? Signs of a failing starter motor include a clicking sound when attempting to start the truck, slow cranking speed, and intermittent starting problems. If you notice these signs, it is advisable to have your starter motor inspected and potentially replaced.

5. Can a faulty alternator affect the starting voltage?

? Yes, a faulty alternator can lead to insufficient voltage for starting the truck. The alternator is responsible for charging the battery while the engine is running. If the alternator fails to provide adequate charge, the battery’s voltage may drop below the required level.

6. Is it normal for the battery voltage to drop after starting the truck?

? Yes, it is normal for the battery voltage to drop slightly after starting the truck. The starter motor draws a significant amount of current, causing a temporary voltage drop. However, the battery should quickly recover and stabilize at the optimal voltage range.

7. Can jump-starting a truck with a higher voltage vehicle cause damage?

? Jump-starting a truck with a higher voltage vehicle can potentially cause damage to the truck’s electrical components. It is crucial to ensure that the jump-starting process follows the correct procedures and uses compatible voltage levels to avoid potential harm.

Conclusion

In conclusion, understanding the voltage requirements for starting a truck is essential for maintaining a reliable and efficient vehicle. The optimal voltage range of 12 to 14 volts provides numerous benefits in terms of performance, compatibility, and cost-effectiveness.

However, it is important to consider individual truck specifications and electrical demands when determining the ideal voltage level. Upgrading to higher voltage systems may be necessary for specialized applications or power-hungry accessories, but it comes with its own set of challenges and considerations.

Ensure regular maintenance of your truck’s electrical system, including the battery, starter motor, and alternator, to maximize its starting capabilities. When in doubt, consult a qualified professional who can provide expert advice tailored to your specific truck model and requirements.

Remember, a well-maintained starting system contributes to the overall longevity and performance of your truck. Take action today to ensure your truck is always ready to hit the road with confidence.

Closing Words

Thank you for reading our comprehensive guide on how many volts a truck needs to start. We hope this article has provided valuable insights into the voltage requirements and considerations for your truck’s starting system.

Always prioritize safety and consult professionals when dealing with electrical systems. Regular maintenance and periodic inspections will help prevent unexpected starting issues and extend the lifespan of your truck’s components.

For more information or personalized advice, feel free to reach out to our team of experts. We are here to assist you in maintaining a reliable and efficient truck starting system.

MyVans Your Vehicle Solution

MyVans Your Vehicle Solution